Backward-Facing Step with Inclined Opposite Wall

Experiments by Driver and Seegmiller

Description

Experimental data have been obtained in an incompressible turbulent flow over a rearward-facing step in a diverging channel flow.

Mean velocities, Reynolds stresses, and triple products that were measured by a laser Doppler velocimeter are presented for two cases of tunnel wall divergence. Eddy viscosities, production, convection, turbulent diffusion, and dissipation (from a balance of the kinetic energy equation) terms are extracted from the data.

Introduction

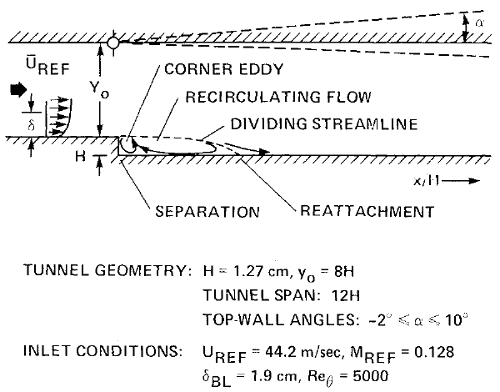

The data present detailed measurements of two cases of reattaching turbulent shear flow behind a two-dimensional rearward-facing step in a diverging channel flow, as shown in figure 1. Diverging the walls produces an adverse pressure gradient on the reattached boundary layer, however, pressure gradient is reduced in the reattachment zone. The experiment was conducted in an incompressible, high-Reynolds-number flow. Channel divergence was accomplished by deflecting the wall opposite the step. A laser Doppler velocimeter (LDV) was used to obtain mean-velocity and turbulence measurements throughout the flowfield. A laser interferometer skin-friction apparatus was used to provide skin-friction measurements along the step-side wall through the separation zone. Turbulent kinetic energy production, convection, and transport by Reynolds stresses and dissipation (inferred from kinetic energy equation balance) have been extracted from the data. These data should be useful in guiding turbulence modelling efforts.

Experimental Details

Test Configuration

The experiments were conducted on the tunnel floor of a low-speed wind tunnel facility.

The test configuration consisted of a 1.0 m long \(\times\) 15.1 cm wide \(\times\) 10.1 cm high rectangular inlet duct followed by a 1.27 cm rearward-facing step in the floor. The wall opposite the step (opposite wall) is hinged at a location 0.6 cm upstream of the step, permitting the wall to be deflected and a pressure gradient to be imposed on the freestream. This test configuration has a large aspect ratio (tunnel-width to step-height ratio of 12) to minimize three-dimensional effects in the separated region, and a small expansion ratio (\((Y_0 + H)/Y_0 = 1.125\)) to minimize the freestream pressure gradient owing to sudden expansion.

The experiment was performed at a freestream velocity of 44.2 m/s and at atmospheric total pressure and temperature. These conditions correspond to a freestream Mach number of 0.128. The step-side wall boundary layer was tripped at a location 1.0 m upstream of the step with a strip of No.60 grit sandpaper 12.5 cm long and 15.2 cm wide (full span). The wall boundary-layer thickness was 1.9 cm, and the Reynolds number (based on momentum thickness) was 5000 at a location 4 step-heights upstream of the step. This high Reynolds number was chosen to ensure that the boundary layer would be fully turbulent before passing over the step.

Two cases of wall divergence are studied in detail:

- parallel-wall case (\(\alpha = 0^o\)) and

- a deflected top-wall (\(\alpha = 6^o\))

The second case resulted in a 30% increase in reattachment length.

Surface and Flowfield Measurement Techniques

Wall static pressures were measured with 0.2 mm-diameter orifices on the tunnel centerline, typically spaced every half-step height through the re-circulating and reattachment zone. The uncertainties in measuring wall pressure led to an uncertainty in the wall static pressure coefficient of -/+0.009 (with 95% confidence limits).

Time-averaged surface skin-friction measurements of the step-side wall were made, using an oil-flow laser interferometer. A drop of oil on the flow (flowing due to skin friction) will reflect laser light at the air-oil interface and from the floor (after having passed through the oil). The two reflected beams are received at a photodiode (where either constructive or destructive interference take place (depending on the instantaneous path length of the the beams). The signal produced is a time record of the change in thickness of the oil on the surface, from which skin friction can be inferred. Skin friction was measured along the step-side wall for both cases of opposite-wall deflection angles. Uncertainties in skin friction were assessed to be -/+8% for a 95% confidence level (with an uncertainty of -/+15% in the separated region the flow).

To detect the instantaneous near-wall flow direction, thermal-tuft probes were mounted in the vicinity of reattachment. The thermal-tuft wall probe employs a central heated wire and two sensor wires (lying parallel to the heated wire), one upstream and one downstream to detect the wake of the central heated wire. All three wires were located approximately 0.25 mm above the floor. The tungsten sensor wires were 0.005 mm in diameter, and the Monel heated wire was 0.125 mm in diameter. Spacing was 1.8 mm and the wires were 3.0 mm long. The resistances of the two sensor wires were compared in a bridge circuit to determine which of the two wires was the hottest, the bridge circuit being balanced before the heater wire was turned on. A positive bridge voltage indicated flow in the downstream direction, and negative voltage indicated flow in the upstream direction. Time-averaging the signal (normalized by the absolute magnitude of the signal) gave intermittency (percent of time the flow direction was downstream). A probe was repositioned along the floor of the tunnel to locate the reattachment point as determined by 50% intermittency.

Measurements of mean velocities, Reynolds stresses, and turbulent triple products were obtained with a two-color laser Doppler velocimeter (LDV). The 0.488 and 0.5145 \(\mu\)m wavelength beams of an argon-ion laser were use to produce two LDV fringe patterns with spacings of 4.48 4.57 \(\mu\)m. The measuring volume was estimated to be less that 0.3 mm in diameter and 1.0 mm long in the spanwise direction. Each of the two pairs of beams had one beam Bragg shifted by 40 MHz to eliminate ambiguity of flow direction. The two channels of LDV were operated simultaneously with beams aligned at +45 and -45 degrees to the axis of the tunnel for measurements of \(U + V\) and \(U - V\) components of velocity. Forward scattered light from particles passing through the measuring volume was detected by photo-multiplier tubes.

The signals from the photo-multiplier tubes were processed in counters that performed five to eight periodicity checks on the signals and digitized the signals with 0.1-ns resolution. Five channels of data were acquired for each valid LD measurement. Two channels were of LDV velocity data, one channel was a time reading from a 100 kHz digital clock, and two channels were of flow direction data near the wall by two thermal tufts (one situated 9.5 mm upstream of reattachment and the other 9.5 mm downstream of reattachment). The two analog signals from the thermal tufts were digitized in an analog-digital converter and all five channels were multiplexed into the buffer of a high-speed digital minicomputer, which recorded the data on magnetic tape. To increase the frequency of measurements, the flow was seeded with 0.5 \(\mu\)m polystyrene spheres which were carried in an alcohol vapour into the plenum chamber of the tunnel. At each measurement location more than 10,000 particles were observed and recorded at a rate that varied from 50 samples/s in the separated zone to 2000 samples/s at the outer edge of the boundary layer. The mean velocities, Reynolds stresses, and turbulent triple products were determined by ensemble-averaging, without applying bias corrections. Ensemble-averaging using a bias correction was determined to be inappropriate for this set of data.

Available Measurements

The data available include:

- Wall skin friction and pressure coefficient distributions along the wall

- Profiles at selected streamwise locations (from \(x/H=-4\) to \(32\)) of mean velocity, Reynolds stresses and triple moments

- Mean velocity profiles at selected spanwise locations, to examine 2-dimensionality of the flow

Sample plots of selected quantities are available.

The data can be downloaded as compressed archives from the links below, or as individual files.

| File | Description |

|---|---|

| bkst-ldv-00.dat | Profiles of mean velocity, Reynolds stresses and triple moments for the \(\alpha=0^o\) case |

| bkst-ldv-06.dat | Profiles of mean velocity, Reynolds stresses and triple moments for the \(\alpha=6^o\) case |

| bkst-tauw.dat | Wall shear stress along the step wall for the \(\alpha = 0^o\) and \(6^o\) cases |

| bkst-cp.dat | Pressure coefficient along the step and top walls for the \(\alpha = -2^o\), \(0^o\), \(6^o\) and \(10^o\) cases |

| bkst-reattach.dat | Tabulated reattachment length vs. top wall incline angle |

| bkst-pitot.dat | Profiles of mean velocity at selected spanwise locations at \(x/H=-4\) and \(36\) for the \(\alpha=0^o\) and \(6^o\) cases |

| bakstp3.dat | Raw data for mean velocity, Reynolds stresses and triple moments |

References

- Driver, D.M., Seegmiller, H.L. (1985). Features of a reattaching turbulent shear layer in divergent channel flow. AIAA J., Vol. 23, p. 163.

Indexed data:

| case030 (dbcase, confined_flow) | |

|---|---|

| case | 030 |

| title | Backward-Facing Step with Inclined Opposite Wall |

| author | Driver, Seegmiller |

| year | 1985 |

| type | EXP |

| flow_tag | 2d, separated, varying_cross_section |