Plane Mixing Layer

Experiments by Delville, Bellin, Garem, Bonnet

Description

The subsonic turbulent plane mixing layer under investigation has the following characteristics: external velocities of Ua=42.8 and Ub=25.2 m/s, fully turbulent co-flowing boundary layers; the test section is 30×30 cm2. Measurements are made both upstream and downstream of the location where the mixing layer should reach an asymptotic, self-similar, state.

Experimental Details

Flow Characteristics

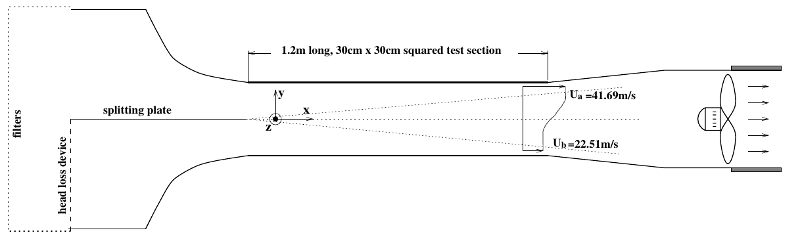

The ML (mixing layer) is created by a flat plate splitting two air streams (Ua=42.8m/s and Ub=25.2m/s; r=Ub/Ua=0.6), as shown in figure 1. The co-ordinates are X in the streamwise direction, Z parallel to the trailing edge and Y normal to the XZ plane (Y=0 at centre line of the ML).

Fig. 1: Flow geometry and configuration

Fig. 1: Flow geometry and configuration

The use of a long splitter plate, with sandpaper strips towards its upstream end, allowed the boundary layers to be fully turbulent by the trailing edge of the plate. The table below summarizes their features.

| Quantities measured at X=−10 mm | Notation | High velocity side boundary layer | Low velocity side boundary layer |

|---|---|---|---|

| Velocity | U∞ | 41.54 m/s | 22.40 m/s |

| Thickness (99%) | δ | 9.6 mm | 6.3 mm |

| Displacement thickness | δ1 | 1.4 mm | 1.0 mm |

| Momentum thickness | θ | 1.0 mm | 0.73 mm |

| Shape factor | H | 1.35 | 1.37 |

| Momentum Reynolds number | Reθ | 2900 | 1200 |

| Turbulence level | u′/U∞ | ≈0.3 | ≈0.3 |

Profiles of mean and rms streamwise velocity just downstream of the splitter plate are available in 0001-ml1.dat.

Experimental Apparatus and Data Processing

This experimental investigation of the plane mixing layer is based on a 12 X hot-wires rake in the mean-gradient direction (Y). Special HW rakes have been designed. A Printed Circuit Board (PCB) and miniature probes fully located inside the PCB are used. The probes have a 1×1 mm2 square section with 0.2mm diameter prongs. Wires are 0.5mm long with a 2.5µm diameter. For holding each probe, a 1×1mm2 groove is machined on the PCB surface. Both X or single probes may be used within the same rake. Velocity can simultaneously be sampled at up to 100 kHz for each of the 24 channels.

The separation between probes is 6mm and the rake extent is about twice the local vorticity thickness δw. By comparing spectra, space time correlations and higher order moments with the corresponding results obtained with conventional one or two single probes, it has been shown that the Hot-Wire-Rake (HWR) does not significantly perturb the flow, at least for the above mentioned characteristics.

Measurements using the X-wire probes have been carried out both in the asymptotic part of the ML (at X=650, 800 and 950 mm), where the mean flow and turbulence profiles are expected to be self-similar and the vorticity thickness to grow linearly, as well as further upstream (at X=150, 200 and 250 mm).

Single hot-wire data have also been obtained at a number of locations, and comparisons of profiles from the two systems show very close agreement.

Available Measurements

Data available includes:

- Development of mixing layer width, and momentum thickness along the channel

- Profiles of mean velocity, Reynolds stresses and triple moments at selected streamwise locations

- Budgets of U momentum, k and ¯uv at X=200 and 800 mm

- Pdf and spectra at selected locations.

Sample plots of selected quantities are available.

The data can be downloaded as compressed archives from the links below, or as individual files.

The files in the tables and links below are profiles and quantities most likely to be used in making comparisons between simulations, for example. The full set of data, from which these have been extracted, and which also contains pdf and spectra data, as well as some further explanatory notes, is available as shl04-files.tar.gz.

| File | Data Contained |

|---|---|

| 0001-ml1.dat | Profiles of mean and rms streamwise velocity just downstream of the splitter plate |

| delom-ml1.dat | Development of vorticity thickness, δω, along the channel |

| theta-ml1.dat | Development of momentum thickness, θ along the channel |

First, second and third order velocity moments:

| Streamwise location | Mean velocities | Reynolds stresses | Triple moments |

|---|---|---|---|

| X=150 mm | 0150-m1.dat | 0150-m2.dat | 0150-m3.dat |

| X=200 mm | 0200-m1.dat | 0200-m2.dat | 0200-m3.dat |

| X=250 mm | 0250-m1.dat | 0250-m2.dat | 0250-m3.dat |

| X=650 mm | 0650-m1.dat | 0650-m2.dat | 0650-m3.dat |

| X=800 mm | 0800-m1.dat | 0800-m2.dat | 0800-m3.dat |

| X=950 mm | 0950-m1.dat | 0950-m2.dat | 0950-m3.dat |

| File | Data Contained |

|---|---|

| kuv-200.dat | k and ¯uv profiles at X=150, 200 and 250 mm |

| kuv-800.dat | k and ¯uv profiles at X=650, 800 and 950 mm |

| eps-200.dat | Dissipation rate profile at X=200 mm |

| eps-800.dat | Dissipation rate profile at X=800 mm |

Budget data:

| File | Data Contained |

|---|---|

| budg-momentum-200.dat | Budget terms from the U momentum equation at X=200 mm |

| budg-momentum-800.dat | Budget terms from the U momentum equation at X=800 mm |

| budg-balancuv-200.dat | Budget terms from the ¯uv equation at X=200 mm |

| budg-balancuv-800.dat | Budget terms from the ¯uv equation at X=800 mm |

| budg-prodk-200.dat | Terms appearing in the k generation at X=200 mm |

| budg-prodk-800.dat | Terms appearing in the k generation at X=800 mm |

| budg-convk-200.dat | Terms appearing in the k convection at X=200 mm |

| budg-convk-800.dat | Terms appearing in the k convection at X=800 mm |

| budg-diffk-200.dat | Terms appearing in the k diffusion at X=200 mm |

| budg-diffk-800.dat | Terms appearing in the k diffusion at X=800 mm |

| budg-eps-200.dat | Dissipation rate of k at X=200 mm |

| budg-eps-800.dat | Dissipation rate of k at X=800 mm |

References

- Delville, J., Bellin, S., Garem, J.H., Bonnet, J.P. (1989). Analysis of structures in a turbulent, plane mixing layer use of a pseudo flow visualization method based on hot-wire anemometry. Advances in Turbulence 2 (Eds. H.H. Fernhols, H.E. Fiedler), Springer Verlag.

Indexed data:

| case034 (dbcase, free_flow) | |

|---|---|

| case | 034 |

| title | Plane Mixing Layer |

| author | Delville, Bellin, Garem, Bonnet |

| year | 1989 |

| type | EXP |

| flow_tag | 2d, mixing_layer |